Ceramic Printed Circuit Boards (PCBs) by H-CELERITY PCB LIMITED

H-CELERITY PCB LIMITED specializes in the manufacture of high-quality Ceramic Printed Circuit Boards (PCBs), which are designed to meet the stringent demands of industries requiring exceptional thermal conductivity, electrical insulation, and mechanical stability. Our ceramic PCBs are engineered using state-of-the-art process technologies and materials to deliver unparalleled performance and reliability.

Key Technologies

Direct Bond Copper (DBC): This technology involves bonding a thin layer of copper directly onto a ceramic substrate using a high-temperature process. DBC is ideal for applications requiring high thermal conductivity and excellent electrical insulation, making it perfect for power electronics and high-power LED applications.

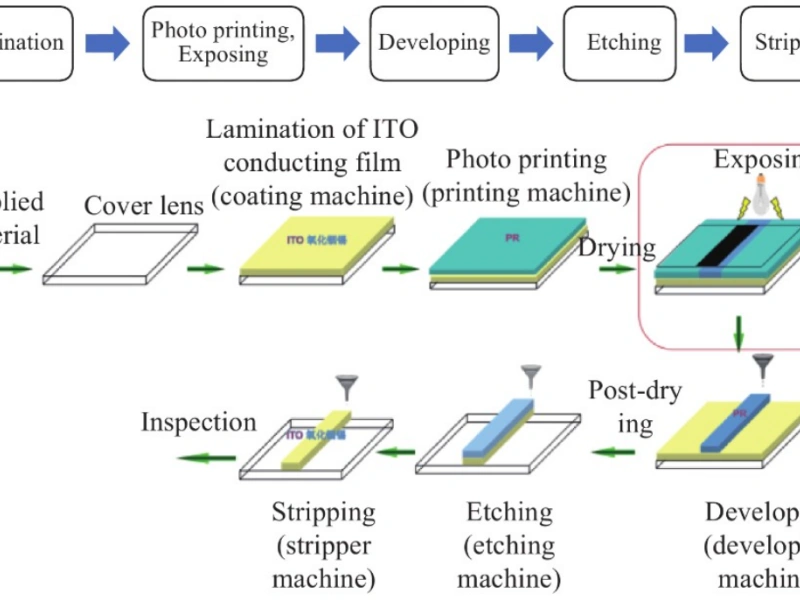

Direct Plated Copper (DPC): Utilizing photolithographic techniques, DPC allows for the precise deposition of copper layers on the ceramic substrate, enabling fine-line circuits and high-frequency performance. This technology is particularly useful in RF and microwave applications.

Active Metal Brazing (AMB): AMB utilizes brazing alloys to join copper to the ceramic substrate, allowing for the creation of complex structures and high-temperature applications. This technology is often used in aerospace and defense sectors.

High-Temperature Co-fired Ceramics (HTCC): HTCC involves printing conductive pastes (containing metals like tungsten or molybdenum) onto a green (unfired) ceramic tape, which is then co-fired at high temperatures. This results in a dense, reliable structure suitable for high-temperature environments.

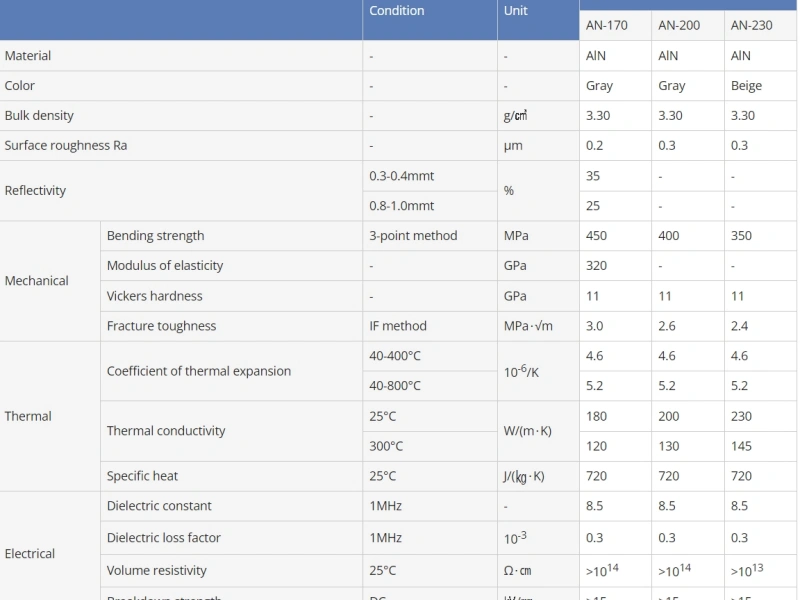

Common Materials

Leading Manufacturers

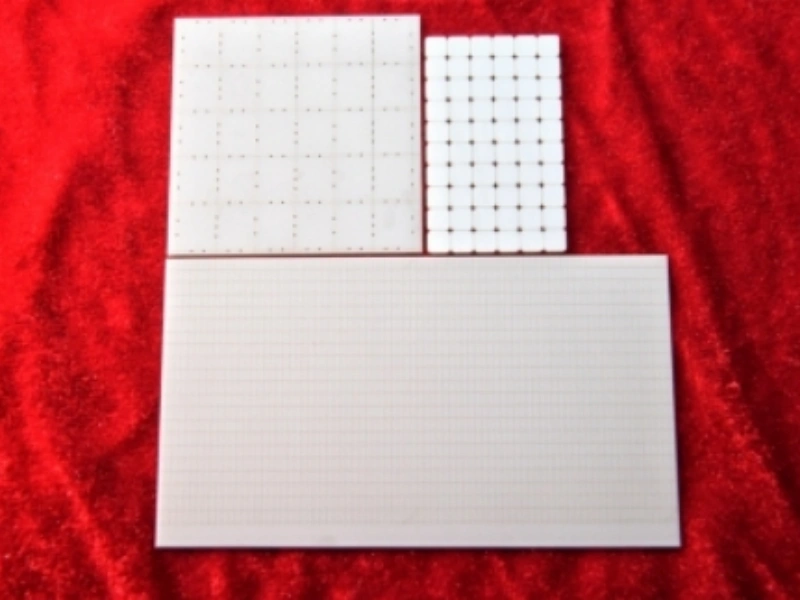

General Dimension

Item | Unit | Type |

AN-170 | AN-200 | AN-230 |

Dimension | inch(max) | 5.5"×7.5" | 5.5"×7.5" | 5.0"×7.0" |

Tolerance | ±1% NLT:±0.1㎜ | ±1% NLT:±0.1㎜ | ±1% NLT:±0.1㎜ |

|

Thickness | ㎜ | 0.25~1.5 | 0.25~1.5 | 0.25~1.0 |

Tolerance | ±10% NLT:±0.04㎜ | ±10% NLT:±0.04㎜ | ±10% NLT:±0.04㎜ |

|

Through hole | ㎜ | Φ0.2~ | Φ0.2~ | Φ0.2~ |

Tolerance | ±0.05㎜ | ±0.05㎜ | ±0.05㎜ |

|

Warpage | ㎜ | 0.002/㎜ | 0.002/㎜ | 0.002/㎜ |

Contact Us

If you have any requirements for ceramic PCBs, whether it's for prototyping or mass production, H-CELERITY PCB LIMITED is here to help. Our team of experts will work closely with you to ensure that your custom ceramic PCB meets all your specifications and exceeds your expectations.

For more information or to request a quote, please contact us at sales@h-cpcb.com.

Ceramic Board Materials Classification

Ceramic PCBs utilize different materials to suit specific application requirements. The most commonly used materials include: